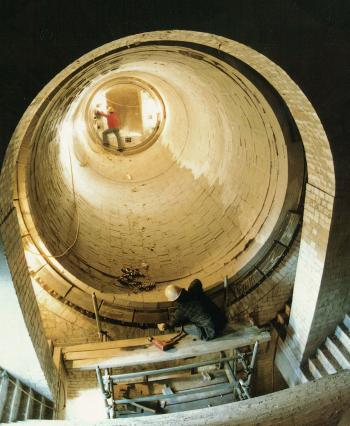

Since its conception in the first half of the century, Industrial Furnace Company has been at the forefront in the design, construction, and preservation of all types of industrial furnaces. Despite its many divisions and diverse areas of endowment, Industrial Furnace Company has maintained excellence in its original ambition. Our refractory lining division, now in its third generation, has played a crucial role in the development of the refractory coating industry. No one in the country can match our proficiency and quality of work.

Contact Us for More Information on Refractory and High Temperature Coatings Service and Supply

Refractory Supplier & High Temperature Coatings Installer:

Industrial Furnace Company’s versatility attracts customers from a wide range of industries. We are qualified to service all types of industrial furnaces, incinerators, reverberatory furnaces, kilns, smelters, and boilers. We are also a top refractory supplier and high temperature coatings installer

Our team of engineers work in conjunction with our clients during the planning phase, actual project start-up, and follow up care.

Our masons and mechanics have been recruited from all parts of the country. In spite of their demographic differences, they are united in a common aim to produce quality and reliable service.

Our employees complete the OSHA General Construction 10-hour course. Some of the topics covered include confined space, respiratory protection, HAZ-MAT, fall protection, scaffolding, and asbestos awareness training. A portion of our crews also receive MSHA and HAZWOPER training as necessary for working in a specific environment. Our safety training records are available upon request.

Refractory Materials Supplier:

The broad spectrum of refractory lining applications from our industry demand a full range of refractory materials. Industrial Furnace Company stocks all classifications of refractories from basic refractories, high alumina, silica, fireclay, insulating, to special purpose refractories. Because “time is money”, we stock materials sufficient enough for the smallest jobs to the most advanced project. Our warehouse, one of the largest in the United States, has the following materials:

Firebrick: all types of firebrick, insulating firebrick, and special shapes.

Monolithic: plastics, castables, gunning mixes, and mortar.

Insulation: block, blanket, mineral wool and ceramic fiber.

Miscellaneous Supplies: crucibles, refractory anchors, pre-cast shapes, tap out blocks, ceramic fiber hardware, furnace castings, high temperature castings, alloy furnace parts and more.

View a listing of some of the refractory products we supply.

High Temperature Coatings and Linings:

We also supply and install a full line of high temperature coatings for refractories, ceramics, metals, and fabrics. These coatings will:

- Increase service life

- Increase corrosion resistance

- Reduce thermal shock and stress

- Decrease refractory porosity

- Provide heat and fire protection (up to 3000 degrees Fahrenheit)